Pay attention to the official Wechat platform and learn more about Epp

As a core part of electric motor, the stator’s quality directly determines the performance and even the safety of the electric motor, the normal stator high voltage test is generally conducted in usual atmospheric pressure, the test voltage is between 1500V to 2500v, but for the tiny insulation broken of winding coil, it is difficult to find out due to the energy capacity shortage of high voltage. To solve this problem, AIP create the vacuum stator tester.

The principle of stator testing in vacuum environment is based on Paschen law, so it is easier to check the winding coil discharge in a vacuum environment. The vacuum we use is not the real vacuum, because there is no discharge in a vacuum, we use a vacuum pump to pump out the air inside the test cover and create a negative pressure environment.

Why the electric motor stator winding coil is easier to discharge in a vacuum, the reason is that an electric current is formed by the movement of free electrons, if a large electric current need to be generated, it needs more free electrons, that means more electrons need to come alive. Electrons have less blinding force at low pressure, so it will be easier to check the discharge of winding coil broken, and find out the defective product.

The conclusion in electrical experiments is that a conductor accumulates electric charge because of the presence of an atmosphere. The atmosphere is ionized into a conductive substance and produces a discharge, which becomes more intense as the atmosphere becomes thinner. Therefore, the stator coil is more likely to discharge in vacuum than in air. So, the air is not an ideal environment for the coil to produce a discharge, and there are some minor insulation breaks that cannot be tested.

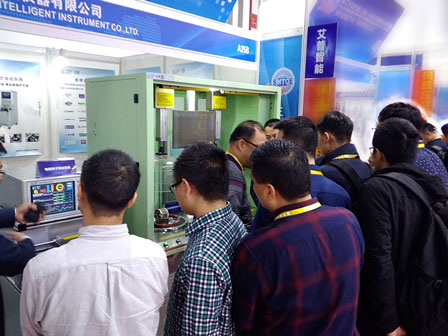

The principle of testing electric motor stator in a vacuum negative pressure was massive proved in lab, and the vacuum motor stator tester is widely accepted by motor manufacturers. Qingdao AIP intelligent Instrument Co., Ltd devoted in the R & D of the vacuum test technology in 2010, provided the first vacuum tester for a foreign- invested company who produce the compressor motor stator. Then this equipment is promoted to different stator manufacturers, improved the overall motor stator testing level of the industry.

随着中国技术的不断发展,电机技术也不断突破,对电机的检测也越来越严格,在真空负压环境的基础上,艾普智能于2018年攻克电机单点破损检测行业难题,专门解决针对线圈只有一个点破损而无法用现有检测方法检出的问题,该技术可替代盐水实验,而不损坏电机,还可以用于产线批量生产,一经推出即轰动整个行业,引起了国内外客户的广泛关注,艾普智能致力于提供一站式电机测试解决方案,选择艾普,就是选择放心。

This article was written by AIP Intelligent Instrument, all rights reserved. Infringement will be investigated. Please indicate the source if reprint: www.aipuo.com